Home

Home

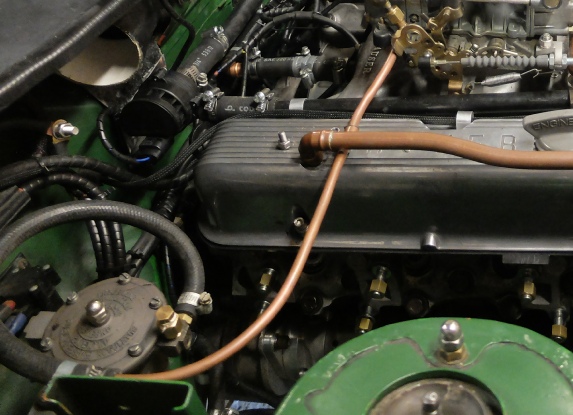

Filter King pressure regulator and filter

Fuel pump

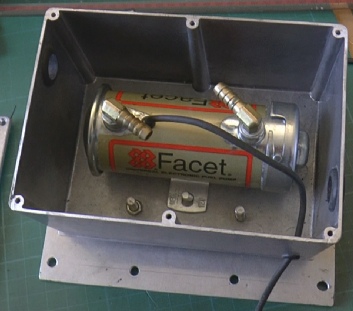

I decided to fit a shiny new fuel pump as I had no idea of the history of the one I inherited with the car. A duff fuel pump is an engine failure which can only be got over with a new pump!

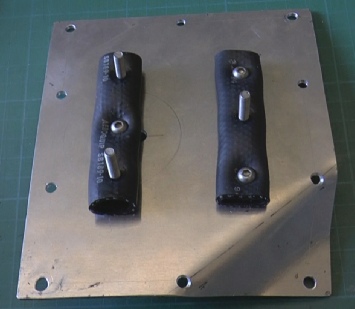

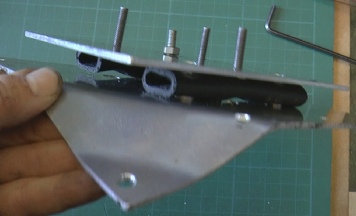

I started by making a plate, with a bit of a bend in the right place which would fit under the car adjacent to the fuel tank. I then made up some anti vibration mounts consisting of two pieces of reinforced heater hose one secured in two places to the mounting plate and I one to the box that would contain the pump and the other piece the other way round (see the picture left).

I used a diecast box to house the pump (Ebay) but I included a piece of 3mm aluminium plate to reinforce the attachment points as the material used in the diecasting is a bit brittle.

The pump makes quite a bit of noise when it runs in the garage without the engine and I thought some vibration insulation from the bodywork would be helpful. In actual fact the noise of the engine even at idle probably drowns it out but the mounting does no harm.

Putting the pump keeps it clean and protects it from water and salt etc. and makes changing or cleaning the filter an easier job.

With a carburettor I always fit a pressure regulator as I don’t trust a needle valve and float to cope with pressures the pump might generate. Also a filter (as long as it’s clean) can’t do any harm. Certainly grot in the needle valve might cause the float chambers to overflow and in the case of the Holly it comes out of the top of the carb possibly onto a hot exhaust.

The static pressure after the regulator should be about 3 -

The Filter King seems to come with a pressure gauge but the recommendation is that it only be used for setting up. Presumably there is a risk it could fail and leak fuel? Similarly you wouldn’t want a mechanical pressure gauge on the dash as the risk of leakage of fuel in the cabin is to be avoided!

Safety circuit

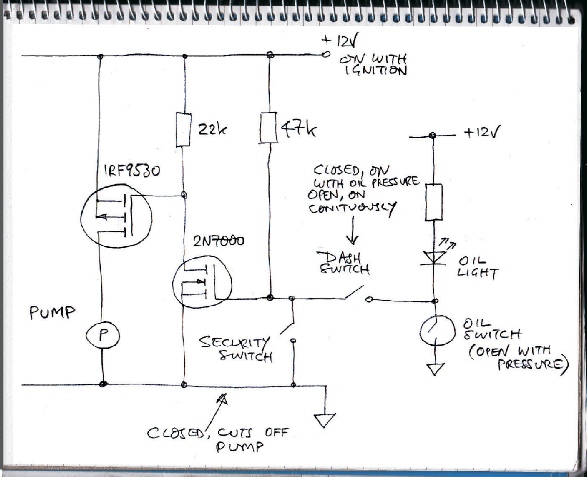

The pump would run all the time the ignition is on so for safety it needs to have its power cut when the engine is not running. This is done by connecting it to the oil pressure switch.

My circuit allows the pump to be run with no oil pressure which is helpful if the float chambers are empty (after parking up for a long time or after a rebuild) by means of a switch. Another hidden switch can be used to disable the pump for security purposes. I made the unit up in a small box fitted behind a modified foot rest in the driver’s footwell. Because the power is switched by a mosfet a tiny toggle switch with a low current capacity can be used.